Quality control

Safety starts with quality!

Quality Control of Materials for Road Signs and Markings

Our products and all materials we use comply with international safety standards. Even in the harshest weather conditions, they ensure clear visibility and durability, providing the highest level of safety during operation.

Materials Used for Road Signs:

- Reflectivity of retroreflective materials (Types I, II, III, IV)

- Strength and corrosion resistance of metal posts (steel, aluminum, etc.)

- Quality of paint and protective coatings

- Compliance with GOST, EN, and other international standards

Materials Used for Road Markings:

- Wear resistance and adhesion of thermoplastics, cold plastics, and paints

- Reflectivity and fade resistance of glass beads

- Compliance with GOST, EN, and other international standards

Control Methods:

- Laboratory tests for strength and durability

- Inspections using specialized measuring tools

- Verification of certificates and quality passports from suppliers

- Field testing under various weather conditions

Fundamentals of quality control

Guaranteed reliability and quality in every product

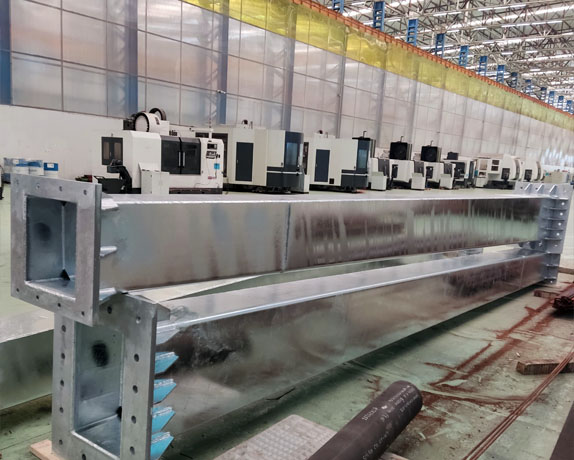

STP-BTECH LLC adheres to high standards in the production of traffic sign poles (Type-LTP) and the quality of welded joints. With an integrated management system based on international standards (ISO 9001, ISO 14001, ISO 45001) and internal requirements, each product earns the trust of our clients.

STP-BTECH LLC ensures the reliability of every product through modern equipment, experienced specialists, and a strong commitment to international standards. For us, quality is not just a standard — it's a commitment!

Material selection and supply

- The use of high-quality steel is certified.

- All materials are supplied with certificates of origin.

Control of technological processes

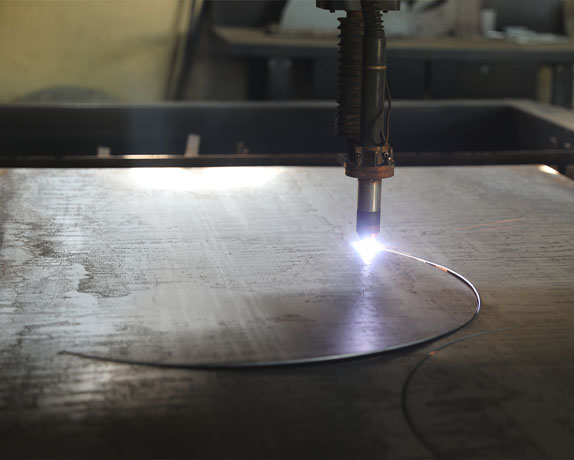

- Cutting: Thermally cut parts are cleaned, and edges are prepared smooth and rounded.

- Welding: Performed by certified welders according to ISO 15614-1 and AWS D1.1 standards. Weld seams are inspected visually and with measuring instruments.

- Visual inspection: 100% visual control is carried out under 350 lux lighting conditions.

Hot-dip galvanizing and corrosion protection

- Galvanizing is carried out in accordance with GOST 9.307-2021 standard.

- Uncoated areas (not exceeding 0.5% of the total surface) are repaired using zinc dust or thermal spraying according to ISO 2063-2 standard.

Documents ensuring quality assurance

- Welding procedure specification (WPS) and procedure qualification records (PQR)

- Welder certifications and dimensional inspection protocols

- Hot-dip galvanizing and visual inspection reports